Posted by Zosi Team

Sound the alarm – your facility received a positive pathogen result, like listeria or salmonella. How can you address the issue? Are you prepared to eliminate the source and not just the symptoms? A corrective action plan allows you to detect and fix a problem that occurred during food production, including actions associated with a corrective action procedure.

So, where do you begin?

In this blog, we outline three necessary aspects of successful corrective action plans you can use to improve your environmental monitoring and safeguard your facility.

Initiating Your Corrective Action Plan

A positive or presumptive positive pathogen result in any zone of your Environmental Monitoring Program (EMP) should trigger a corrective action.

As you move through your corrective action plan, ensure thorough documentation of all investigations conducted, steps taken, and include a complete description of the trigger. It helps to define a responsible party or person who can handle initiating, completing, and documenting corrective actions.

While FDA regulated facilities need not conduct pathogen testing on zone 1, USDA regulated facilities must test zone 1 for pathogens or pathogen species. The corrective action would have to consider the required inputs depending on the regulatory body.

Intensify Cleaning

The USDA requires intensified cleaning and sanitation immediately following a positive sample of a pathogen. FDA regulated facilities should follow similar steps as those recommended by the USDA. Begin by identifying all possible harborage sites and cross-contamination pathways in your facility. Consider employee traffic routes or product moving equipment, like pallet jacks and forklifts, during this process.

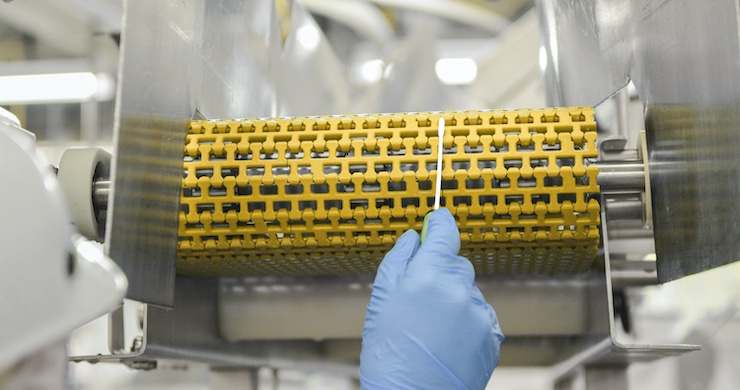

Next, fully disassemble and clean the equipment. The means of sanitation depends on your machinery’s sanitary design. Intensified cleaning should always include deep cleaning, high sanitizer concentration application to the affected equipment and surrounding areas with adequate residual time, and then rinse and final sanitizer application at normal concentration.

If you continue to see positive pathogen results, you may need to repair or replace the equipment in question.

Note that the surrounding production areas and supporting equipment are subject to additional monitoring and cleaning activities. Regard them as potential harborage areas until your corrective action proves successful.

Swab Your Way to Success

Look at the size of your operation and the type of products you produce to determine what kind of follow-up sampling method you’ll enact as part of your corrective action plan. Your chosen method should include 2 to 3 sets of swabbing performed in the days after an initial positive result.

When swabbing these areas, consider vectoring. Vector swabbing is a method based on the location of the original positive sample. To learn more about the process of vector swabbing, consult our online Environmental Monitoring Program training.

During this process, you may need to quarantine the area from any personnel traffic or product movement to prevent any additional contamination.

Holding Procedures and Root Cause Analysis

If a zone 1 test in your facility receives a positive pathogen sample, consider whether all affected finished products should be placed on hold or under quarantine after sanitization, pending the corrective action and retest results.

Of course, to truly eliminate harmful bacteria and mitigate risk, you need to know the root cause source. In other words, you need to determine the underlying cause of the situation. Where did the bacteria originate? How did it enter your facility?

If you find a root source not incorporated into your corrective action, there’s a good chance that corrective action proves ineffective. Always consider root cause analysis as part of your corrective actions, not a step to take after the fact.

Summary

To ensure you’re not consistently battling the same issues on the production floor, you need to implement thorough corrective actions. After detecting a pathogen, take care to sanitize the area and surrounding equipment beyond daily cleaning routines. You may need to quarantine the area while you get to the root of the risk and conduct retests until negative results prove the bacteria is no longer present in your facility.

Remember, an effective EMP’s objective is to identify potential pathogen harborage areas that could become sources of contamination and serve as verification of a company’s sanitation program.

The Zosi Solution

As per 21 CFR 117 Subpart B, any facility that handles ready-to-eat (RTE) and microbiologically sensitive foods must develop an environmental monitoring program to mitigate inherent food safety risks. Our online EMP training course helps you improve your program and corrective action plan for continued food safety success.

Corrective and Preventive Action (CAPA) Fundamentals

Corrective and Preventive Action (CAPA) Fundamentals

Environmental Monitoring Program

Environmental Monitoring Program

Course Bundle – Corrective and Preventive Action & Root Cause Analysis

Course Bundle – Corrective and Preventive Action & Root Cause Analysis